Description

Brand new model of BREWMASTER 50 liter wort brew machine.

More brewing, less accessories.

Now even newer: like the original, but better. This is a BREWMASTER 50 liters with a welded double cooling jacket.

For a long time, we had the problem of how to equip the smallest BREWMASTER brewhouse with a cooling jacket. And now we have finally done it. The new BREWMASTER 50 liters has as great features as its bigger brothers.

Double cooling jacket welded directly in the factory make some accessories unnecessary and provide more freedom in your brewing art. Now you can make your beer easier than ever before.

For easy emptying of the pan, another spout is connected to the bottom of the tank, which makes it easier to clean the brew.

The fully automatic control system prepares the beer wort according to preset or your own individual recipes. Times and temperatures are strictly observed in all phases of the cooking process. Unlike the cumbersome equipment of some other hobby brewery manufacturers, BREWMASTER does not have to be constantly mixed. Thanks to the patented technology of the malt basket, during heating the wort circulates in the brewhouse in a purely based on thermal principe, and the active substances are leached from the malt grains very gently and efficiently. During the cooking of the wort, there is no undesired overburning and caramelization of the malt, because the malt is not in direct contact with the heating elements.

What’s new about this great brewhouse model?

- New larger touch screen – the control is now supplied with a 5-inch touch screen, with water resistance up to IP 65.

- The temperature measurement is even more accurate than before, because the temperature sensor is now built directly into the guide bar. This means that it is exactly in the middle of the malt mash and outside the turbulence cone.

- The WLAN module is no longer required – it is already integrated directly into the new controller and software updates are now available, which are performed automatically if the customer so wishes.

- The new version also comes with a new malt basket with 6 screws.

- The stainless steel pump is newly equipped with a potentiometer which can be used to regulate its speed.

- From now on, the pause time of the pump can also be set individually.

- Made of stainless steel AISI 304

- Capacity: 25 l of produced beer (applies to normal beer) = approx. 55 l of wort

- Note: Using the cooling jacket on the BREWMASTER does not work properly with a shortened malt basket and half the amount of wort.

Technical parameters and equipment:

Specifications :

- Heating coil: power 3200 W

- Pump: 27 W – with adjustable speed

- Power supply: 230 V (fuse min. 10 amp.)

- Control system: fully automatic control of the brewing process (temperature, time, pump)

- Max. amount of malt: 13 kg

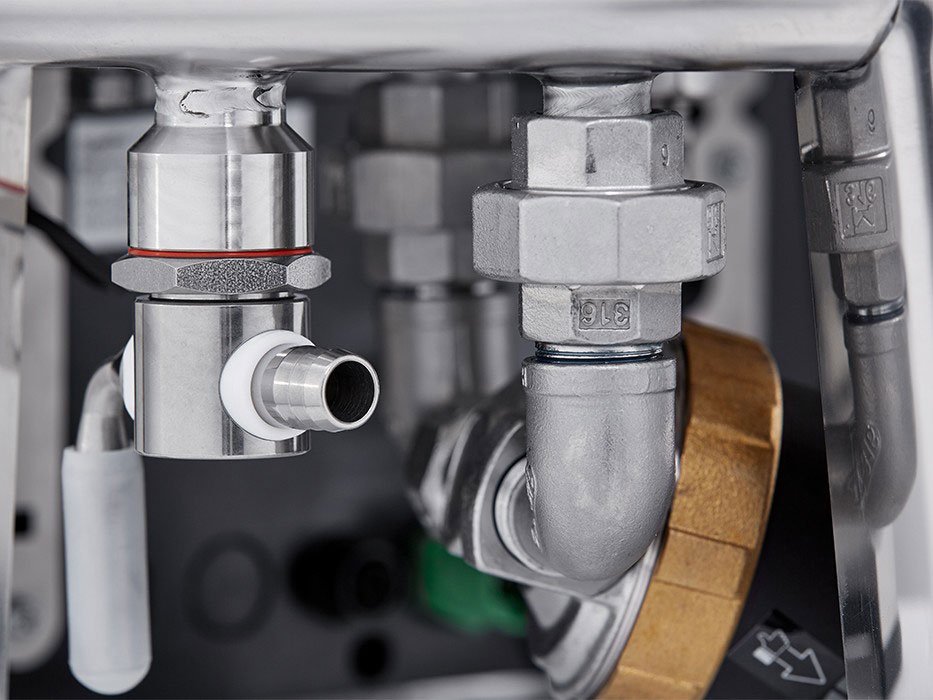

- Built-in double jacket for efficient brewing of wort

- Additional drain cock G ¾ “at the bottom of the tank

- Connectors to jacket 1″ ET 2x inclusive Gardena connectors

Dimensions

- Height: 70 cm

- Diameter: 50 cm

- Carton dimensions: 74 x 60 x 61 cm (length x width x height)

- Shipping weight: 37 kg

Benefits :

- The brewhouse fits easily into a smaller area – brew beer directly on the kitchen counter.

- Easy handling during beer brewing and cleaning, only the small force needed to lift the malt basket is enough.

- The patented malt basket system, circulating the wort from the bottom up against gravity, results in efficient and gentle leaching of the active ingredients from the malt grains, you will not find any pipes on the outside of the vessel in the brewhouse.

- Automatic control of the brewing process with color display, status lights, memory for 10 recipes, automatic mode, timer and the ability to download many more recipes via the internet application.

- Smooth welds mean easy cleaning of the brewhouse.

- Easy to repair: all elements are easily removable, equipped with screw connections, it is easy to remove, for example, the pump, sensors, etc., so that really everyone can replace a defective part.

- The firmware of the BREWMASTER brewhouse always remains up-to-date via communication with the Internet (via the wifi module). This ensures compatibility with new devices and accessories that are constantly being developed by our team.

- BREWMASTER fit perfect the needs for the Low Oxygen Brewing (with using an extra accesory)

Control software:

- Brewing guide – shows also the required quanity and kind of raw materials

- Exakt temperature measuring

- Help informations in all the brewing process

- Pump pauses are adjustable

- Integrated Wifi for software updates over the air, sync of recipes with the special app

- Integrated data base of raw materials

- Timer functions

- Option for additional accessories for auto cooling of wort

- Ferment control for the option to beer fermentation directly in the Braumeister machine

- Ferment control allows use data of the hydrometer

Wort brewing process :

Programming – Depending on the recipe, the BM-50 brewing system is programmed with the appropriate brewing times and temperatures. The brewing process starts by switching over to automatic control. The control system guides the user through the step by step and executes all four brewing phases automaticaly.

Mixing and heating of malt mash – Depending on the recipe and method, you poure water into the BREWMASTER machine and heat it up to 38 °C. Then put the malt basket with the sieve in its working position. Pour required amount of malt between the sieve inserts. The malt basket is fixed with bracket and drawbar.

Mash brewing – The pump switches on automaticaly. During the malt in water circulation process, he starch is extracted from the malt. The four wort brewing phases are executed according to recipe is selected. For example as follows:

- Protein phase : 55 °C, approximately 5 min

- Maltose phase : 63 °C, approximately 30 min

- First sacharidation phase : 72 °C, approximately 20 min

- Second sacharidation phase : 78 °C, approximately 10 min

Filtering – At the end of the four mashing phases an acoustic signal sounds. The subsequent wort filtering process is easy executed by simply removing the malt basket from the BREWMASTER machine. In the case of the BM-200 and bigger machines this is done by means of the integrated lifting device. Allow to filtrate the wort through malt a few minutes. Then shortly sparge the malt in the basket by hot water to achieve a better yield and remove the malt basket.

Boiling the wort with hops – The wort is boiled for 80 minutes with hops , with opened lid. Hops being added several times during the boiling. Using a special sieve you can easy to separate hops pellets from wort. The evaporated water is to be replaced by adding fresh brewing water. The original wort viskosity can be finally adjusted by adding or leaving out water. Scale on the wort brew machine serves as a level meter. At the end of the boiling phase, an acoustic signal sounds again.

Wort cooling – After end of the boiling the wort with hops, the wort is cooled as soon as possible to the fermentation temperature by a special wort cooler directly inside the machine or using the cooling double jackets of the fermenting tank cooled with cold water and water cooler.

Beer fermentation/maturation process :

Immediately after end of the boiling of the wort the temperature of the wort is brought to the level of the fermentation temperature by a wort cooler or by a double jacket; the wort is also mixed with yeast and fermented in a suitably large fermentation tank (optional accessory).

Reviews

There are no reviews yet.